Electro Magnetic Separators

Advanced, Automatic Iron Removal for Continuous Material Handling

ISC Electro Magnetic Separators are designed to provide powerful, reliable, and continuous tramp iron removal in industrial environments. These separators are essential for ensuring smooth, efficient operations in material handling systems by automatically detecting and removing unwanted iron from your material flow. Whether you're working with bulk materials on conveyors or processing heavy loads, our magnetic separators offer the perfect solution to protect your equipment, maintain product quality, and enhance operational efficiency.

- ISC GROUP

In-Line Magnetic Separator

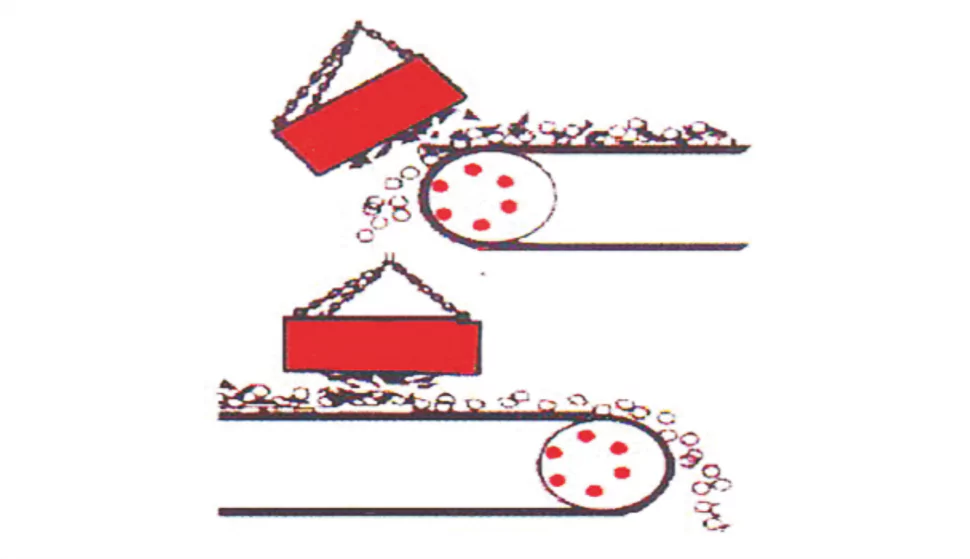

The In-Line Magnetic Separator is designed to be suspended at the discharge point of a conveyor, where it automatically removes tramp iron in the same direction as the conveyor’s travel. Installed at an angle over the material discharge point, it operates as a self-cleaning, suspended magnetic separator. The key advantage is that it discharges collected iron away from the processed material, ensuring a seamless operation. This design is particularly essential when dealing with long iron pieces like roof bolts or drill rods, as the In-Line Separator prevents these from damaging conveyor belts. Its ability to handle long iron pieces without jamming or tearing expensive conveyor sections makes it an indispensable choice for many industries.

Cross Belt Magnetic Separators offer continuous and automatic removal of tramp iron. Suspended above the conveyor, the powerful rectangular magnet pulls out unwanted iron, while a self-cleaning belt discharges the iron into a receptacle placed beside the conveyor, keeping it away from the material in process. Since the suspended magnet continuously cleans itself, there is no need to stop the conveyor, ensuring uninterrupted operation and efficient protection of your conveyor system from tramp iron damage.

- ISC GROUP

Cross Belt Magnetic Separator